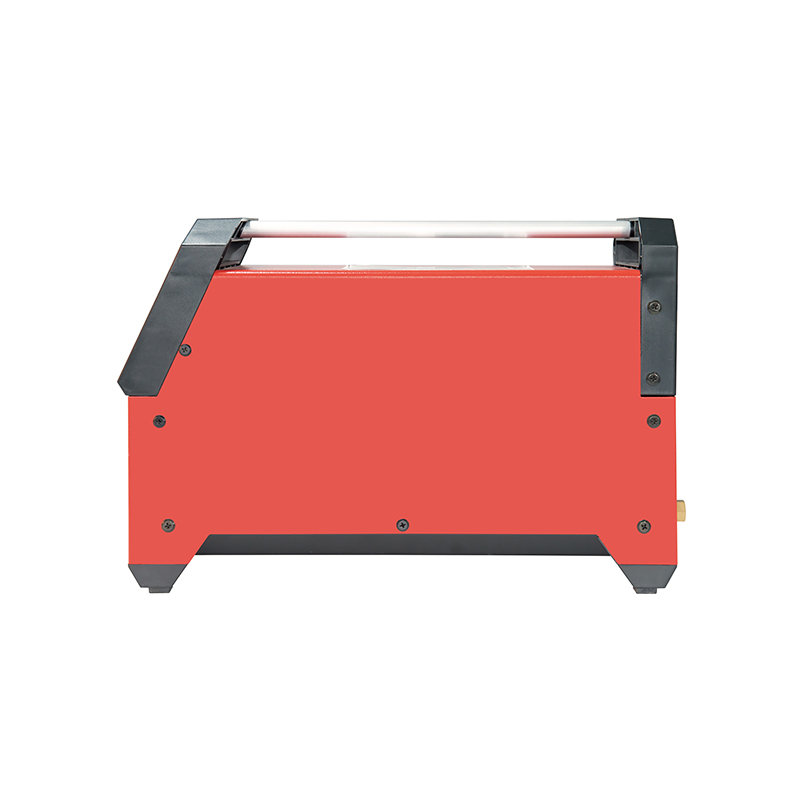

CUT40/60H CUT40/60NH Inverter Igbt Series For Plasma Cutter Industry Knowledge Expansion

What are the key features and advantages of the Cut40/60h Inverter IGBT Plasma Cutter?

The Cut40/60h Inverter IGBT Plasma Cutter is a cutting-edge tool designed for precision metal cutting. Here are some of its key features and advantages:

- High Precision Cutting: The Inverter IGBT technology used in this cutter allows for highly precise and clean cuts, making it suitable for various applications, including metal fabrication, automotive repair, and DIY projects.

- Wide Cutting Range: This cutter offers a wide cutting range, making it versatile for handling different materials and thicknesses. It can cut through metals such as steel, stainless steel, copper, and aluminum with ease.

- Compact and Portable: The Cut40/60h is compact and lightweight, making it easy to transport and use in various locations. Its portability is particularly useful for on-site jobs or in workshops with limited space.

- IGBT Technology: The use of Insulated Gate Bipolar Transistor (IGBT) technology enhances the cutter's efficiency and reliability. It provides stable and consistent cutting performance while reducing energy consumption.

- User-Friendly Interface: The cutter features a user-friendly interface with adjustable settings for cutting speed and intensity. This allows both beginners and experienced users to achieve precise results.

- Safety Features: Safety is a priority, and the Cut40/60h is equipped with safety mechanisms such as overheat protection and voltage fluctuation protection. These features not only protect the cutter but also ensure the safety of the operator.

- Durable Construction: The cutter is built to withstand rugged usage. Its durable construction ensures a longer lifespan, making it a cost-effective choice for professionals.

- Air Plasma Cutting: It utilizes air plasma cutting, which eliminates the need for expensive and cumbersome gas cylinders. This makes the Cut40/60h more cost-efficient and convenient.

What are the notable features and benefits of the Cut-40/60nh IGBT Inverter Plasma Cutting Machine?

The Cut-40/60nh IGBT Inverter Plasma Cutting Machine is a versatile tool designed for efficient metal cutting. Here are its notable features and benefits:

- Cutting Versatility: This machine is known for its versatility in cutting various metals, including steel, stainless steel, aluminum, and copper. Its wide cutting range makes it suitable for a range of applications.

- IGBT Technology: The inclusion of IGBT technology ensures stable and consistent cutting performance. It allows for efficient energy use, which is both cost-effective and environmentally friendly.

- User-Friendly Interface: The user interface is designed with ease of use in mind. Operators can adjust cutting parameters, such as cutting speed and intensity, to achieve precise results quickly.

- High Cutting Speed: This machine is known for its high cutting speed, which improves efficiency and reduces project completion times. It's a valuable asset for professionals working on time-sensitive projects.

What are the key features and advantages of the Cut-60 IGBT Inverter Plasma Cutting Machine?

The Cut-60 IGBT Inverter Plasma Cutting Machine is a high-performance tool designed for precision metal cutting. Here are its key features and advantages:

- Precision Cutting: The Inverter IGBT technology ensures precise and clean cuts, making it suitable for various applications, including metal fabrication, automotive repair, and industrial tasks.

- Wide Cutting Range: The machine offers a wide cutting range, allowing it to handle different materials and thicknesses effectively. It can cut through metals such as steel, stainless steel, copper, and aluminum.

- Compact and Portable: Its compact and lightweight design makes it highly portable and suitable for on-site work or workshops with limited space.

- IGBT Technology: The IGBT technology enhances the cutter's efficiency, providing stable and consistent cutting performance while reducing energy consumption.

- User-Friendly Interface: The machine features an intuitive user interface with adjustable settings for cutting speed and intensity. This ensures ease of use and precise results.

- Safety Mechanisms: Safety features, including overheat protection and voltage fluctuation protection, ensure the safety of both the equipment and the operator.

- High Cutting Speed: The Cut-60 is known for its high cutting speed, which increases productivity and reduces project completion times. It's an excellent choice for tasks requiring efficiency.

dd@chndd.com

dd@chndd.com  +86-576-86177723 / +86-576-86219978

+86-576-86177723 / +86-576-86219978

English

English 中文简体

中文简体 Español

Español русский

русский