CT312/416/520 GD Inverter IGBT Series for Plasma Cutter Industry Knowledge Expansion

What are the key features and advantages of the Cut MMA Hf TIG Inverter IGBT Plasma Cutter?

The Cut MMA Hf TIG Inverter IGBT Plasma Cutter is a versatile and advanced welding and cutting machine designed to meet the needs of professionals in various industries. Its key features and advantages include:

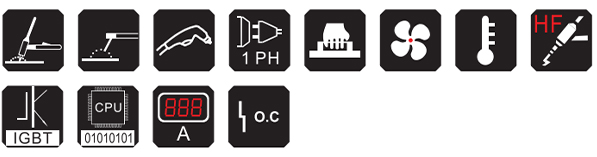

- Multifunctionality: This cutter combines multiple welding and cutting processes in one machine, including MMA (Manual Metal Arc) welding, TIG (Tungsten Inert Gas) welding, and plasma cutting. This versatility makes it suitable for a wide range of applications.

- High-Frequency Start: The high-frequency start feature ensures a quick and reliable ignition for both TIG welding and plasma cutting. It minimizes the risk of electrode contamination and allows for precise and clean starts.

- IGBT Technology: The use of IGBT (Insulated Gate Bipolar Transistor) technology enhances the cutter's performance. It provides high efficiency, stable current output, and excellent arc control, resulting in better welding and cutting quality.

- Digital Display: The digital display panel allows for easy adjustment of welding and cutting parameters. It provides real-time feedback on settings, making it convenient to fine-tune the machine according to the specific requirements of the task.

- Cutting Capability: The plasma cutting function of this machine is capable of cutting various metals, including steel, stainless steel, aluminum, and more. It offers a clean and precise cutting process with minimal dross.

What are the key benefits of a Current Digital Display IGBT Plasma Cutter?

A Current Digital Display IGBT Plasma Cutter is a valuable tool in the field of metalworking and fabrication. Its key benefits include:

- Precise Control: The digital display allows for accurate adjustment of current settings, which is crucial for achieving desired welding and cutting results. Users can easily set and monitor the current, ensuring consistent quality.

- IGBT Technology: The incorporation of IGBT technology provides superior performance in terms of energy efficiency and stable current output. It contributes to cleaner and more controlled arcs during welding and cutting processes.

- Versatility: A Current Digital Display IGBT Plasma Cutter is suitable for cutting a wide range of materials, from thin sheets to thicker plates. Its versatility makes it an indispensable tool for metalworkers, fabricators, and welders.

- Ease of Use: The digital display simplifies the machine's operation. Users can quickly adjust settings and easily monitor the current, voltage, and other parameters, even in challenging work environments.

- Durability: These cutters are built to withstand the rigors of industrial use. They are designed for longevity and reliability, ensuring that they can handle demanding tasks over time.

What are the key features that make the Ct-520gd Inverter IGBT Series For Plasma Cutter applications?

The Ct-520gd Inverter IGBT Series For Plasma Cutter is a powerful and versatile solution for plasma cutting. Its key features that set it apart in plasma cutting applications include:

- Dual Functionality: This series combines both TIG welding and plasma cutting functions in a single machine, providing exceptional versatility for users. It allows for both precision cutting and welding with ease.

- IGBT Technology: The use of IGBT technology enhances the cutter's performance. It delivers a stable and efficient current output, ensuring clean and precise cuts in various metals, including steel, aluminum, and stainless steel.

- Adjustable Parameters: Users can easily adjust cutting parameters, including current, with precision. The machine offers flexibility to adapt to different cutting tasks and materials.

- Portability: The series is designed to be portable and easy to transport to various job sites, making it suitable for on-site work and projects that require mobility.

- Safety Measures: Safety is a priority, and the series incorporates features such as overheat protection and voltage compensation to ensure user safety during operation.

dd@chndd.com

dd@chndd.com  +86-576-86177723 / +86-576-86219978

+86-576-86177723 / +86-576-86219978

English

English 中文简体

中文简体 Español

Español русский

русский