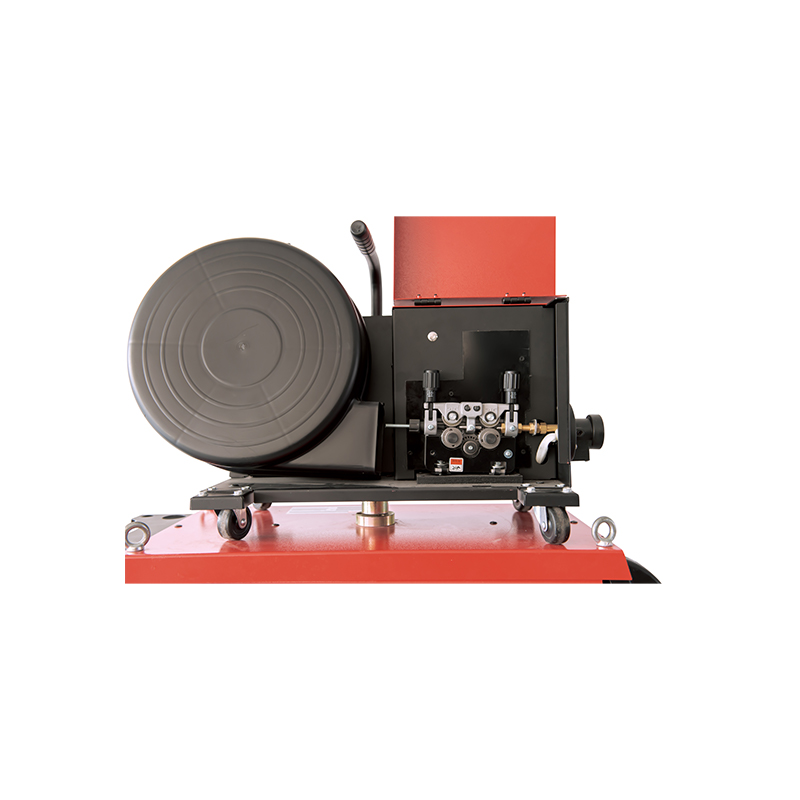

MIG 400/500 GFW Inverter IGBT Module Series for MIG/MAG Welder Industry Knowledge Expansion

What are the key features that set the IGBT Module Inverter Welder Max MIG 400 apart in the world of welding equipment?

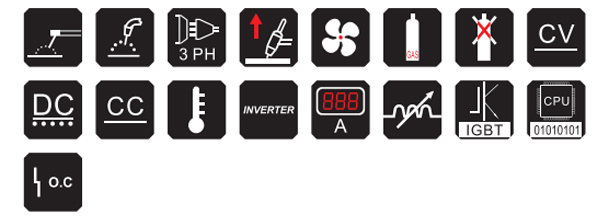

The IGBT Module Inverter Welder Max MIG 400 distinguishes itself with a range of standout features. This welding machine harnesses the power of Insulated Gate Bipolar Transistor (IGBT) technology to deliver exceptional welding performance. Its key features include:

1. High Efficiency: The IGBT module ensures high energy efficiency, reducing power consumption and operating costs.

2. Versatility: It offers a versatile welding experience, suitable for various welding processes, including MIG (Metal Inert Gas) and MAG (Metal Active Gas) welding.

3. Advanced Control: The machine's inverter technology provides precise control over welding parameters, enabling welders to achieve optimal results.

4. Compact Design: Its compact and portable design makes it suitable for both on-site and workshop welding applications.

5. Durability: With robust construction and built-in safety features, it is designed to withstand challenging working conditions.

What advantages does the MIG-500 MIG MAG IGBT Inverter Welding Machine offer to professionals in the welding industry?

The MIG-500 MIG MAG IGBT Inverter Welding Machine is tailored to meet the demands of welding professionals, providing numerous advantages, including:

1. Powerful Performance: With a welding capacity of up to 500 amps, it can handle a wide range of welding tasks, from thin sheets to thick materials.

2. IGBT Technology: The use of IGBT technology ensures efficient energy use, resulting in lower operational costs.

3. Multi-Process Capability: This machine supports both MIG (Metal Inert Gas) and MAG (Metal Active Gas) welding processes, enhancing versatility and adaptability.

4. User-Friendly Interface: An intuitive control panel allows welders to easily adjust settings and parameters, making it suitable for both beginners and experienced professionals.

5. Reliability: Built with durability in mind, it offers consistent and reliable welding performance even in demanding industrial environments.

How does the IGBT Module Industrial Welding Machine contribute to improved productivity and efficiency in industrial welding applications?

The IGBT Module Industrial Welding Machine is a game-changer in the world of industrial welding, offering significant benefits in terms of productivity and efficiency. Here's how:

1. High Power Output: With its IGBT module technology, it delivers high power output, allowing for faster welding speeds and increased productivity.

2. Wide Amperage Range: It offers a wide amperage range, making it suitable for welding various materials and thicknesses, thereby reducing the need for multiple machines.

3. Precision Welding: The machine's advanced control and monitoring systems ensure precise welding results, reducing the need for rework and improving overall weld quality.

4. Energy Efficiency: IGBT technology enhances energy efficiency, resulting in reduced electricity consumption and cost savings over time.

5. Industrial Durability: Designed for industrial use, it can withstand rigorous work environments and extended periods of operation without compromising performance.

In summary, these three welding machines, the IGBT Module Inverter Welder Max MIG 400, MIG-500 MIG MAG IGBT Inverter Welding Machine, and IGBT Module Industrial Welding Machine, offer a range of features and advantages that cater to the diverse needs of welding professionals, from efficiency and versatility to durability and precision. Their utilization of IGBT technology sets them apart in the welding industry, making them valuable assets for welding applications of all kinds.

dd@chndd.com

dd@chndd.com  +86-576-86177723 / +86-576-86219978

+86-576-86177723 / +86-576-86219978

English

English 中文简体

中文简体 Español

Español русский

русский