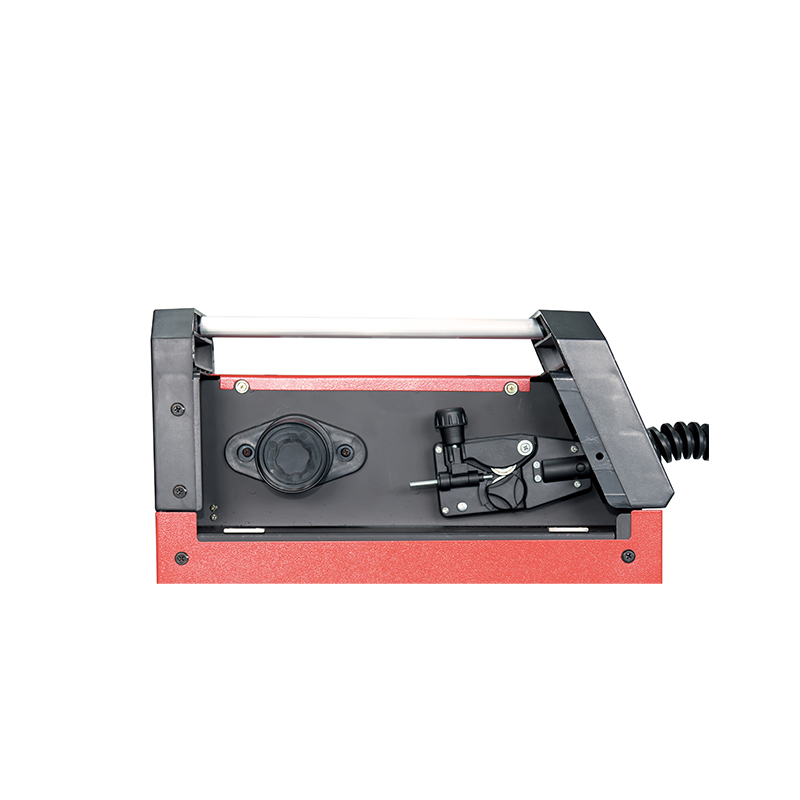

MIG 135/155G Inverter IGBT Series for MIG/MAG Welder Industry Knowledge Expansion

What are the key features and advantages of the MIG 135 Inverter IGBT MIG/MAG Welder?

The MIG 135 Inverter IGBT MIG/MAG Welder is a compact and versatile welding machine designed for a range of applications. Its key features and advantages include:

1. Inverter Technology: This welder utilizes advanced inverter technology, specifically IGBT (Insulated Gate Bipolar Transistor), which offers excellent control over the welding process. It provides precise and stable welding arcs, making it suitable for both beginners and experienced welders.

2. Portability: The MIG 135's compact design and lightweight construction make it highly portable. It's easy to transport to various job sites, enabling welders to work in different locations with ease.

3. Versatility: This welding machine is capable of both MIG (Metal Inert Gas) and MAG (Metal Active Gas) welding processes. It's versatile enough to handle various materials, including steel, stainless steel, and aluminum, making it a valuable tool for a wide range of welding projects.

4. Adjustable Parameters: The MIG 135 offers adjustable welding parameters such as voltage and wire speed, allowing welders to fine-tune settings to match the specific requirements of each welding task. This versatility ensures high-quality welds across different materials and thicknesses.

5. User-Friendly Interface: Its user-friendly control panel simplifies the setup process. Welders can easily select the welding mode, adjust parameters, and monitor the welding status, even if they have limited experience with welding equipment.

6. Efficiency: Inverter-based welding machines are known for their energy efficiency. The MIG 135 consumes less power while delivering robust welding performance, reducing energy costs in the long run.

7. Reliability: With a reputation for durability and reliability, this welder is built to withstand demanding working conditions, ensuring longevity and minimal downtime.

What distinguishes the MIG 155g Inverter IGBT MIG/MAG Welder from other welding machines?

The MIG 155g Inverter IGBT MIG/MAG Welder stands out for several reasons, making it a top choice among welders:

1. Enhanced Power: This welding machine offers higher power output compared to the MIG 135, making it suitable for welding thicker materials and handling more challenging welding tasks.

2. Welding Capacity: The MIG 155g can tackle a wider range of materials, including carbon steel, stainless steel, and aluminum, thanks to its robust performance capabilities.

3. Multi-Process Capability: Similar to the MIG 135, it supports both MIG and MAG welding processes, providing flexibility for various welding applications.

4. Advanced Control: With precise control over welding parameters, welders can achieve superior weld quality. Adjustments to voltage and wire speed are effortless, ensuring optimal results.

5. Improved Duty Cycle: The MIG 155g boasts an enhanced duty cycle, allowing for longer periods of continuous welding before needing to cool down. This feature is particularly useful for extended welding projects.

What are the advantages of using the MIG MAG IGBT Inverter Welding Machine in industrial applications?

The MIG MAG IGBT Inverter Welding Machine offers several advantages that make it a preferred choice for industrial welding applications:

1. High Efficiency: This welding machine excels in terms of efficiency, delivering precise and consistent welds while optimizing energy consumption. In industrial settings, efficiency is critical for maintaining productivity.

2. Versatility: The MIG MAG IGBT Inverter Welding Machine supports both MIG and MAG welding processes, making it adaptable to various industrial welding needs. It can handle a wide range of materials and thicknesses.

3. Advanced Control Features: Industrial applications often demand precise control over welding parameters. This welding machine provides advanced controls, including digital displays and programmable settings, enabling welders to fine-tune their welding processes for optimal results.

4. Durability and Reliability: Industrial environments can be demanding, but the durability and reliability of the MIG MAG IGBT Inverter Welding Machine ensure consistent performance and minimal downtime.

5. Cost-Effective: While offering advanced features, this welding machine is designed to be cost-effective in the long term. Its efficiency and productivity benefits contribute to reduced operational costs.

dd@chndd.com

dd@chndd.com  +86-576-86177723 / +86-576-86219978

+86-576-86177723 / +86-576-86219978

English

English 中文简体

中文简体 Español

Español русский

русский