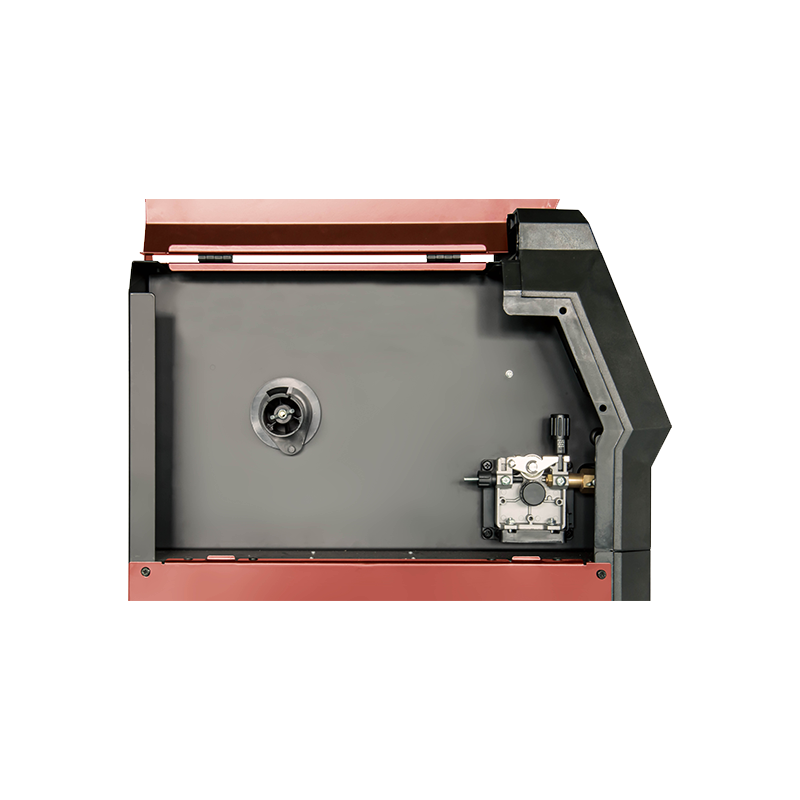

MT200 AC DC Inverter IGBT Series for MIG/MAG Welder Industry Knowledge Expansion

What are the key advantages of using the Mt200 AC DC Inverter IGBT Series For MIG/MAG Welder?

The Mt200 AC DC Inverter IGBT Series For MIG/MAG Welder offers several key advantages:

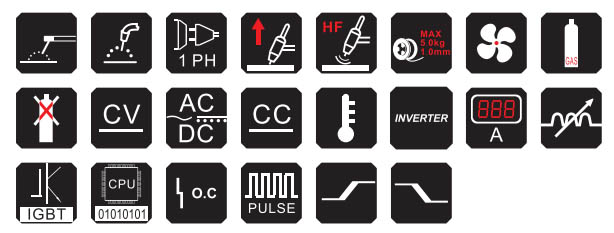

1. Versatility: This inverter welder is designed for both AC and DC welding, providing versatility for a wide range of applications.

2. Advanced Technology: It incorporates IGBT (Insulated Gate Bipolar Transistor) technology, ensuring stable and efficient welding performance.

3. Precise Control: The welder allows for precise control over welding parameters, including voltage and current, resulting in high-quality and consistent welds.

4. Portability: Its compact and lightweight design makes it highly portable, ideal for on-site welding projects.

5. Energy Efficiency: IGBT technology enhances energy efficiency, reducing power consumption and operating costs.

6. Reliability: The Mt200 AC DC Inverter IGBT Series For MIG/MAG Welder is known for its reliability and durability, ensuring long-term performance.

In summary, the Mt200 AC DC Inverter IGBT Series for MIG/MAG welding combines versatility, advanced technology, precise control, portability, energy efficiency, and reliability. These additional advantages, such as wider material compatibility, smooth arc characteristics, digital displays, safety features, convenient setup, and reduced post-weld cleanup, make it a preferred choice for welders seeking optimal performance and efficiency in their welding operations.

How does the DC Inverter IGBT MIG/MAG Welder contribute to efficient and effective welding processes?

The DC Inverter IGBT MIG/MAG Welder offers several benefits that contribute to efficient and effective welding:

1. Stable Arc: It provides a stable welding arc, reducing spatter and ensuring precise control during the welding process.

2. Wide Amperage Range: The welder offers a wide amperage range, allowing for welding of various materials and thicknesses.

3. Ease of Use: Its user-friendly interface and controls make it easy for welders of all levels of experience to operate.

4. Compact Design: The compact and lightweight design enhances portability, making it suitable for various work environments.

5. Adaptive Voltage: It adapts to fluctuations in input voltage, ensuring consistent performance even in challenging conditions.

6. Durability: Built with high-quality components, this welder is known for its durability and longevity, reducing maintenance costs.

What advantages does the AC Inverter IGBT MIG/MAG Welder offer for welding tasks that require alternating current?

The AC Inverter IGBT MIG/MAG Welder provides several advantages for welding tasks that necessitate alternating current (AC):

1. Excellent Penetration: AC welding is particularly suitable for materials like aluminum and magnesium, where it provides excellent penetration and weld quality.

2. Cleaning Action: AC welding offers a cleaning action that removes oxide layers and contaminants from the base metal, ensuring strong and clean welds.

3. Wide Range of Applications: It is versatile and suitable for a wide range of applications, including fabrication, automotive, and aerospace industries.

4. Controlled Heat Input: Welders can control the heat input precisely, minimizing the risk of distortion or burn-through on thin materials.

5. Enhanced Weld Appearance: AC welding produces aesthetically pleasing welds with minimized discoloration and spatter.

6. Efficiency: Inverter technology enhances energy efficiency, reducing operating costs and environmental impact.

In summary, the AC Inverter IGBT MIG/MAG Welder offers advantages in terms of penetration, cleaning action, versatility, controlled heat input, weld appearance, and efficiency when dealing with AC welding applications.

dd@chndd.com

dd@chndd.com  +86-576-86177723 / +86-576-86219978

+86-576-86177723 / +86-576-86219978

English

English 中文简体

中文简体 Español

Español русский

русский